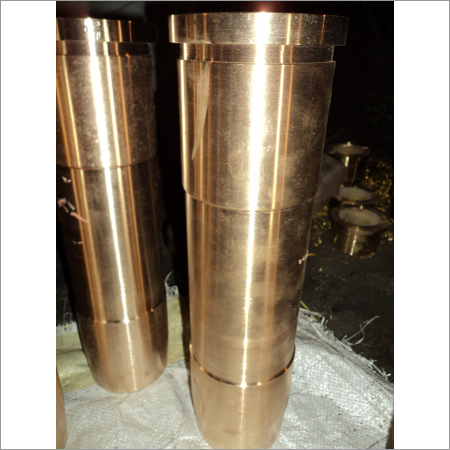

Phosphor Bronze Bushes

Product Details:

- Size 2 Inches

- Color Bronze

- Usage Industrial

- Product Type Phosphor Bushes

- Material Phosphor Bronze

- Finish Polished

- Click to View more

Phosphor Bronze Bushes Price And Quantity

- 900 INR/Unit

- 1 Unit

Phosphor Bronze Bushes Product Specifications

- Polished

- Phosphor Bushes

- Phosphor Bronze

- 2 Inches

- Industrial

- Bronze

Phosphor Bronze Bushes Trade Information

- 1000 Unit Per Month

- 7-10 Days

- All India

Product Description

Due to their special qualities, phosphor bronze bushes have a number of benefits:

1. Phosphor bronze has good wear resistance, which qualifies it for use in applications requiring high levels of friction and constant sliding action. Without suffering significant wear, it can survive challenging environments and big weights.

2. Low friction: The low coefficient of friction of phosphor bronze bushes lowers heat generation and energy loss during operation. This property helps mating surfaces move smoothly and effectively together.

3. Phosphor bronze bushes are appropriate for locations where exposure to moisture, chemicals, or other corrosive factors is a concern since the bronze alloy's phosphorus content boosts its corrosion resistance.

4. High strength: Phosphor bronze is capable of withstanding enormous loads and resisting deformation under pressure thanks to its strong mechanical properties.

Numerous industries, including the automotive, aerospace, marine, industrial machinery, and more, use phosphor bronze bushes. They are frequently utilised in shafts, gears, pumps, valves, and other parts where reliable performance and rotating movement are necessary. Phosphor bronze is chosen for certain applications based on variables such load capacity, speed, temperature, and environmental circumstances.

Although phosphor bronze bushes operate well in many applications, it's important to keep in mind that for maximum effectiveness and durability, certain design, lubrication, and maintenance considerations must be made.

| Surface Finishing | Polished |

| Is It With Alloy | Without Alloy |

| Material | Phosphor Bronze |

| Brand | Crescent Casting Corporation |

| Casting Temperature | Upto 750 Degree Celsius |

| Usage/Application | Vehicle Suspension |

| Country of Origin | Made in India |

| Size/Diameter | 2 inch |

FAQ

1. What are bronze-colored phosphor bushes?

Ans - Phosphor bronze bushes are bushings constructed of phosphorus-containing bronze alloys, which make them resistant to corrosion and wear. They are frequently found in heavy machinery, machine parts, and engines.

2. What advantages do phosphor bronze bushes offer?

Ans - Phosphor bronze bushes have great wear resistance, high strength, and excellent corrosion resistance qualities. Additionally, they are exceptionally workable and heat resistant.

3. How are phosphor bronze bushes made?

Ans - Casting or machining are both used to make phosphor bronze bushes. The procedure calls for a mould and includes a difficult heating and cooling cycle for cast items. A lathe or milling machine is used in the machining process to produce the desired form and dimension.

4. What phosphor bronze grades are offered?

Ans - Phosphor bronze is available in a number of grades, including C711XX, C836XX, and C907XX. These grades are categorised according to how much copper, phosphorous, and tin they contain; consequently, each category will have a different set of qualities.

5. How are phosphor bronze bushes maintained?

Ans - Phosphor bronze bushes need to be oiled and checked for deterioration on a regular basis. Avoid exposing the bushings to high temperatures or vibrations, as these conditions might damage the bearings. To prevent further breakdowns and potential accidents, it is best to repair the bushings as soon as possible if they get corroded or broken.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free