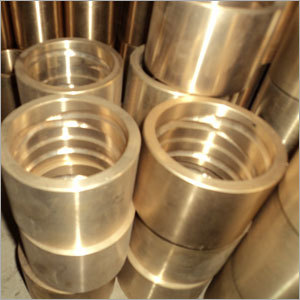

Brass Castings

Product Details:

- Product Type Cast Products

- Material Brass

- Surface Finishing Polished

- Color Golden

- Click to View more

Brass Castings Price And Quantity

- 50 Kilograms

- 550 INR/Kilograms

Brass Castings Product Specifications

- Cast Products

- Brass

- Polished

- Golden

Brass Castings Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 1000 Kilograms Per Month

- 7 Days

- All India

Product Description

Castings made of brass are items or parts that were created with this metal during the casting process. Copper and zinc make up the majority of the alloy called brass, though other elements may be added to give it particular qualities.

Similar to other casting techniques, the process of casting brass typically entails the following steps:

1. Pattern creation: Materials like wood, wax, clay, or 3D printing are used to make a pattern or model of the intended thing. The blueprint depicts how the brass casting will ultimately look.

2. Making a mould: Using a mould material, such as sand, plaster, or ceramic, a mould is created around the pattern. To allow for the removal of the pattern and the following pouring of molten brass, the mould is often produced in two or more portions.

3. Removal of the pattern: The mold's cavity is left with the shape of the desired product after the pattern has been taken out.

4. Casting of brass: Sprues and gates are channels via which molten brass, which is produced by melting brass alloy, is poured into the cavity of the mould. The mould is filled with the molten brass, which assumes the pattern's shape.

5. Cooling and solidification: Inside the mould, the molten brass cools and solidifies, taking on the pattern's shape.

6. Mould removal and finishing: The casting is cleaned and finished once the mould has been removed and the brass has cooled. It might be necessary to remove any extra material, polish it, and use any surface treatments that are required.

Numerous industries, including plumbing, the automotive, maritime, electrical, and decorative arts, make extensive use of brass castings. A variety of objects, including valves, fittings, hardware, sculptures, musical instrument parts, and more, contain them. Brass is a common material for casting applications because it has exceptional strength, excellent corrosion resistance, and an appealing look.

| Color | Golden |

| Finishing | Polished |

| Usage/Application | Industrial |

| Tolerance | +/- 0.05 mm |

| Casting Type | Metal Casting |

| Packaging Type | Box |

| Material | Brass |

| Country of Origin | Made in India |

FAQ

1. What metal alloys are used in castings of brass?

Ans - A copper and zinc alloy is typically used in castings of brass, however occasionally other elements like lead, iron, or aluminium are included as well.

2. How are castings made of brass machined?

Ans - For brass castings, the machining process usually entails drilling, sawing, milling, turning, tapping, and honing.

3. How long does it take to cast brass?

Ans - Depending on how sophisticated the object is, the brass casting process might take anything from a few hours to many days.

4. How should brass castings be maintained?

Ans - Cleaning brass castings with warm water and a light detergent or vinegar solution is the best way to maintain them. When finished, make sure to rinse them and polish them with a soft towel.

5. Are castings made of brass corrosion-resistant?

Ans - Due to the alloy nature of brass, it naturally resists corrosion. To further thwart corrosion, they can also be given protective coatings or plated with other metals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free